Reducing Packaging Costs Without Sacrificing Performance: A Distributor’s Guide

In a competitive market, distributors are constantly looking for ways to reduce costs while maintaining the high level of performance required for packaging. Reducing packaging costs without sacrificing performance might seem challenging, but with the right approach, it’s possible to strike a balance between cost and quality. In this guide, we’ll explore how distributors can cut costs while ensuring that packaging remains durable and efficient for transit and storage. Whether you’re operating in New York or anywhere nationwide, these strategies will help you achieve cost savings.

Choosing the Right Materials for Cost-Effective Durability

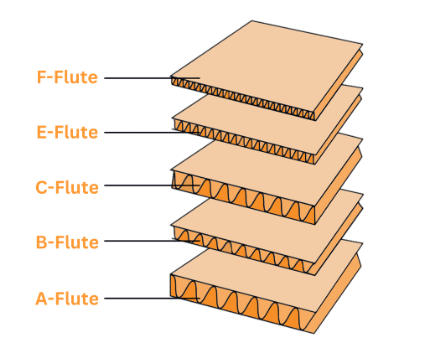

One of the best ways to reduce packaging costs without sacrificing performance is to choose the right materials. Not all packaging materials are created equal, and by selecting cost-effective yet durable options, distributors can maintain quality while lowering expenses. For example, corrugated cardboard, especially E Flute, offers strong protection at a lower cost compared to bulkier materials.

Additionally, exploring recyclable or biodegradable materials can cut costs while aligning with eco-friendly trends. These materials are often lighter, reducing shipping fees, while still providing sufficient protection during transit.

Streamlining Packaging Design to Reduce Waste

Reducing waste is another crucial way to lower packaging costs without compromising performance. Custom packaging that fits the product precisely reduces the need for excess materials such as fillers or padding. By designing packaging that optimizes the use of space, distributors can lower material usage and shipping costs.

Furthermore, streamlined packaging designs help minimize damage, ensuring products are well-protected without adding unnecessary bulk. This approach not only cuts costs but also improves supply chain efficiency by allowing more products to fit into each shipment.

Bulk Purchasing for Economies of Scale

Another effective way distributors can reduce packaging costs is by taking advantage of bulk purchasing. Ordering packaging materials in larger quantities can often lead to significant cost savings. While the upfront cost may be higher, the long-term savings from reduced material costs and fewer orders will add up.

Working with suppliers like W Packaging, who offer flexible pricing for bulk orders, can help distributors access high-performance materials at a more affordable rate, whether you’re in New York or anywhere else nationwide.

Multi-Functional Packaging for Performance and Cost Efficiency

Multi-functional packaging solutions offer another way to reduce costs while maintaining performance. Distributors can choose packaging that serves multiple purposes, such as providing both protection and branding. For example, well-designed boxes that double as marketing tools or product displays can save money on additional materials while still enhancing the unboxing experience for customers.

By consolidating the packaging functions into one solution, distributors can cut down on unnecessary packaging components, saving costs without sacrificing quality.

Minimizing Shipping Costs with Lightweight Packaging

Choosing lightweight yet durable materials is essential for cutting shipping costs without compromising performance. Lightweight packaging materials, such as certain types of corrugated cardboard or biodegradable plastics, can lower shipping fees by reducing the overall weight of shipments.

In addition to saving on shipping, lightweight packaging is easier to handle, improving warehouse efficiency and reducing labor costs. Ensuring the packaging remains strong enough to withstand transit is key, but many lightweight materials provide the perfect balance between protection and cost savings.

Cost-Effective Packaging for Distributors Nationwide

Reducing packaging costs without sacrificing performance is possible when distributors choose the right materials, streamline designs, and take advantage of bulk purchasing. Whether you’re in New York or operating anywhere nationwide, W Packaging can help you cut costs while maintaining the durability and performance needed for transit and storage. Contact W Packaging today to explore cost-effective solutions that meet your performance needs!