Corrugated fiberboard, often known as “combined board,” is made up of two basic components: the liner and the medium. Both are made of a type of strong paper known as containerboard. Linerboard is the flat material that clings to the medium, often on the board’s outer surfaces but also on the inner for some structures.

- Flutes

- Combined Board

- Box Designs

The paper shaped into arches or flutes on the single facer and pasted between the linerboard facings is referred to as the medium.

Flutes

An arch with the proper curve was the answer to give strength to span a given space. This principle practiced for centuries led to the application of this principle to paper. The creators put arches in the corrugated medium and created stronger materials. These arches, which are referred to as flutes, are resistant to bending and pressure coming from all sides when they are adhered to the linerboard with an adhesive.

When a piece of combination board is laid on its end, the arches form stiff columns capable of bearing significant weight. The flutes act to keep the linerboard sheets separated, maximizing the board’s bending rigidity. When pressure is applied to the board’s side, the space between the flutes functions as a cushion to protect the contents of the container. The flutes also act as an insulator, protecting the product from unexpected temperature changes. Simultaneously, the vertical linerboard adds strength and shields the flutes from harm.

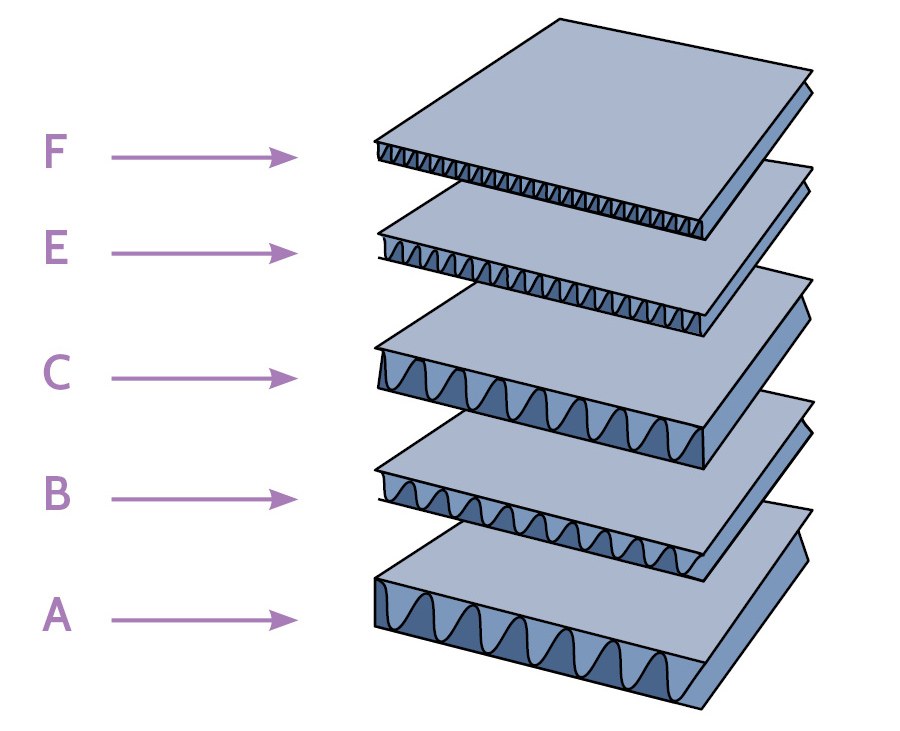

Flutes are classified into various categories. Flutes with the same designation are all the same size, although they might have different flute profiles and number of flutes per foot within the same designation:

- The A flute profile for corrugated board was a flute. It has around 33 flutes per foot.

- The B flute was then designed for self-supporting canned foods that did not require heavy-duty boxes. It has around 47 flutes per foot.

- The C flute was next designed as an all-purpose flute, with around 38 flutes per foot.

- The E flute was the next successful flute profile, with approximately 90 flutes per foot.

- The F flute was designed for compact folding carton boxes. It contains around 125 flutes per foot.

Not only has the number of flute profiles increased in recent years, but so has the diversity in flute characteristic measurements for every given flute profile. Because corrugator rolls are manufactured to meet a variety of issues, the flute profiles will vary, sometimes dramatically (such as speed, paperboard characteristics, economies, etc.).

Combined Board

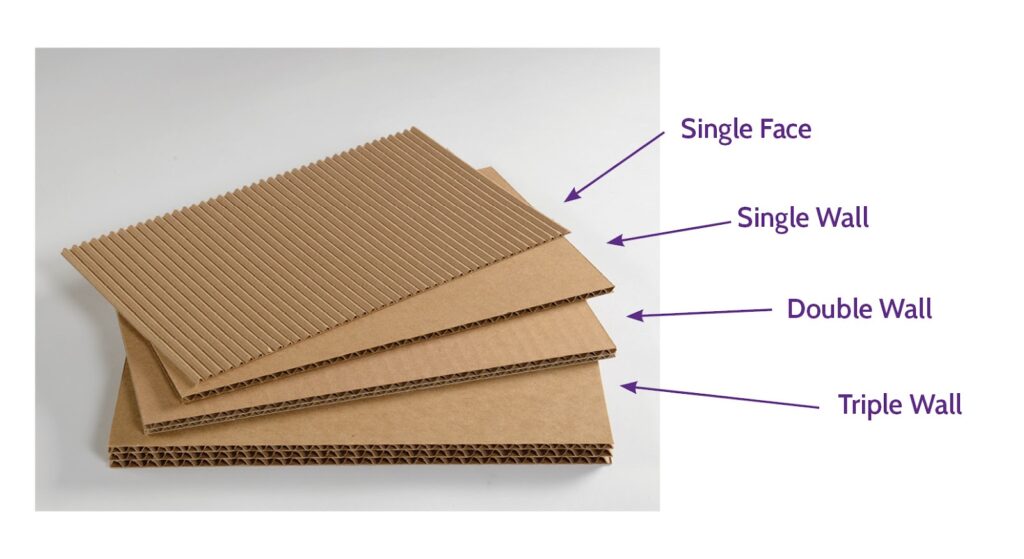

The diagram below depicts four main types of combination board that are most often made from linerboard and medium utilizing various flute structures:

- Single Face: One corrugated medium is adhered to a single flat piece of linerboard.

- Single Wall: The corrugated media is pasted between two sheets of linerboard to form a single wall. Double Face is another name for this.

- Double Wall: Three sheets of linerboard sandwiched between two mediums.

- Triple Wall: Four sheets of linerboard sandwiched between three mediums.

Larger flute profiles provide more cushioning and vertical compression strength, whilst smaller flute profiles provide better graphics capabilities. When opposed to paperboard, smaller flutes such as E and F give improved structural capabilities for primary (retail) packaging (folding cartons). There is also considerable variation across the industry in the spectrum of flute diameters dependent on the container features sought for each application.

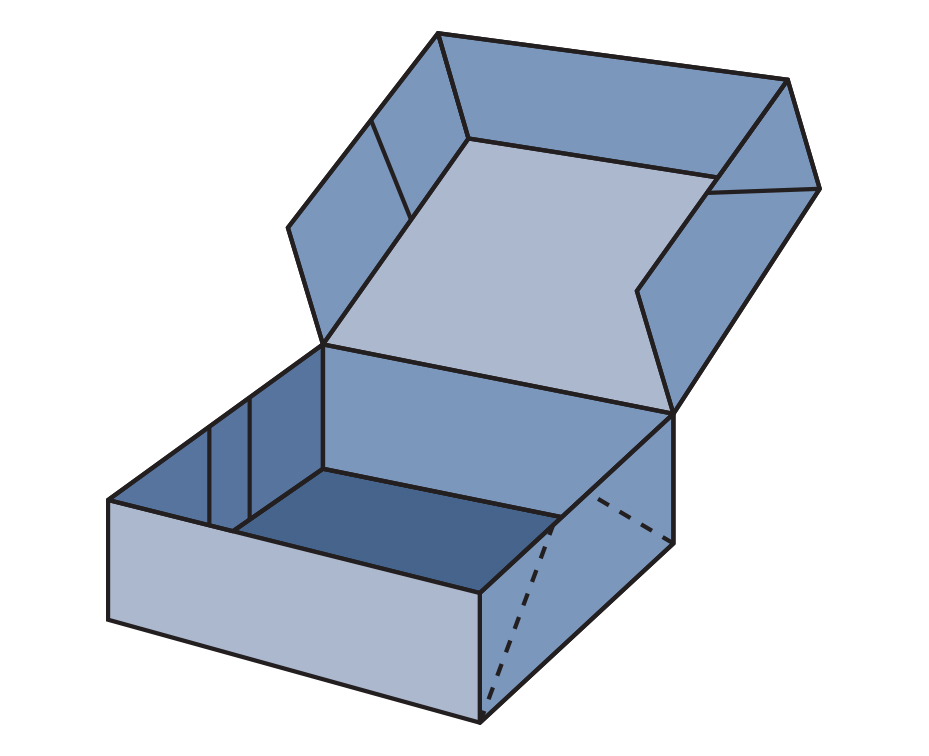

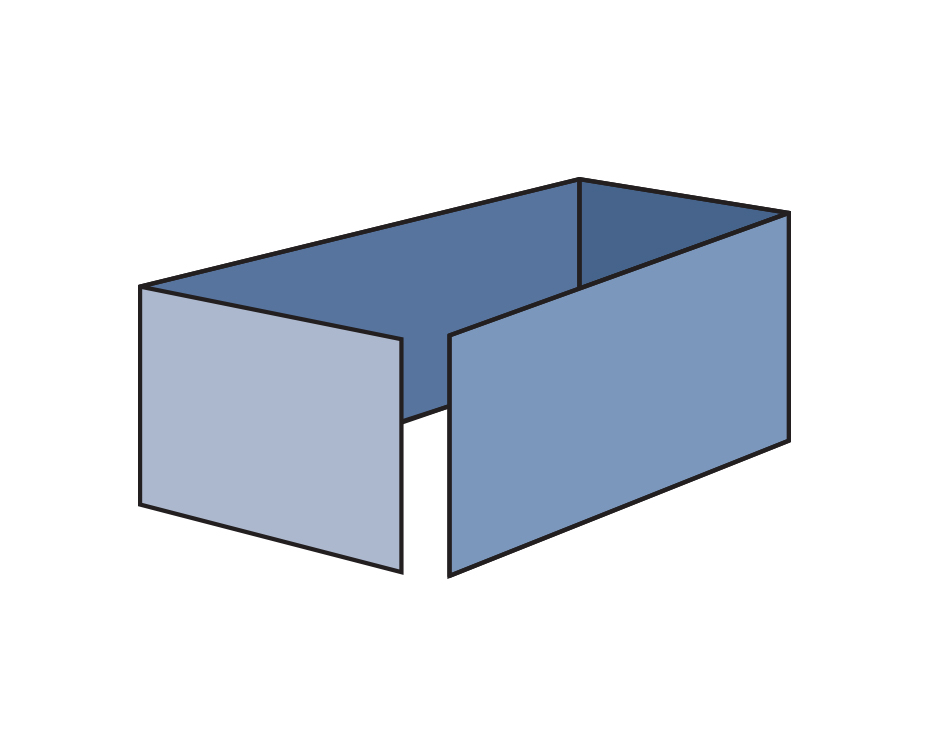

Box Design

Everything from oranges to dishwashers can be shipped in boxes. A corrugated box can be made to efficiently ship and store practically any goods by modifying the form of the box, combining layers of corrugated, or adding inside packaging.

Many common box styles can be identified using one of three methods: a descriptive name, an acronym based on that name, or an international code number. The International Fibreboard Case Code was created by the European Federation of Corrugated Board Manufacturers (FEFCO) in partnership with the European Solid Board Organization (ESBO) to avoid misunderstandings when speaking in different languages.

The following are some popular box style categories and styles. Remember that there are plenty of additional conventional styles from which to choose. Furthermore, corrugated boxes can be specifically constructed to satisfy the needs of any box user. Additional box style variations will be available through a manufacturer’s representative.

Visit www.corrugated.org for more information about corrugated, other organizations aiming to keep corrugated at the forefront of the whole packaging sector, and corrugated career possibilities.

W packaging always working to keep corrugated at the forefront of the entire packaging industry and career opportunities in the corrugated field.

Visit https://wpackaging.net/